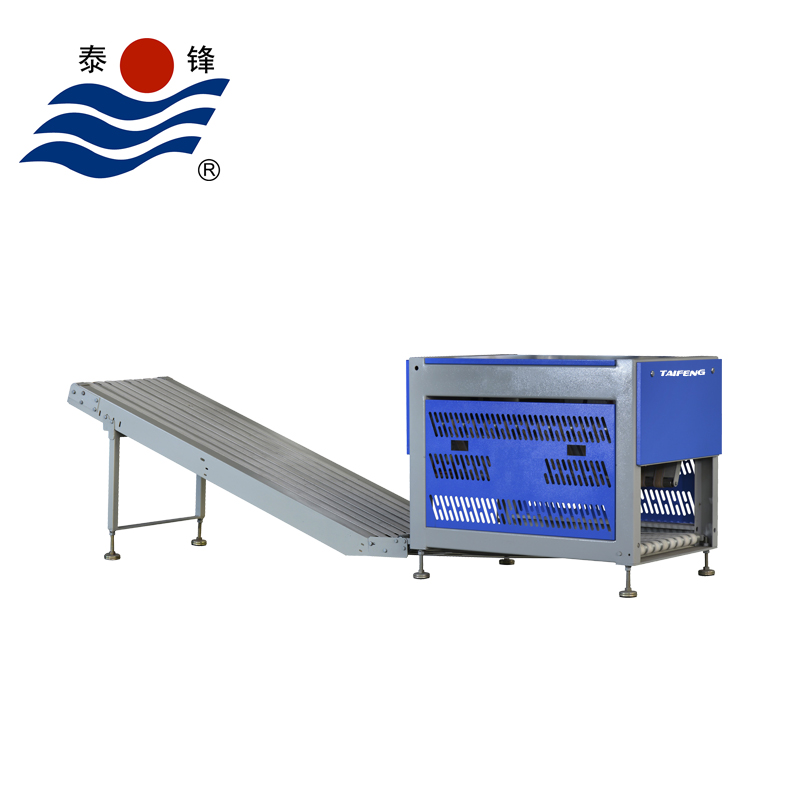

stacker machine

The stacker machine quickly opens the folded cloth through the flap, the lower conveyor belt catches the falling cloth. When reach the pre-selected quantity, the conveyor belt delivery the stacked linen out. One position, to achieve counting and stacking function well. The stacker machine adopts cylinder to directly drive the flap,simple structure, low failure rate the conveyor belt is directly driven by the electric roller, and the conveying length can be sel on the computer.

The conveyor belt adopts the anti-skid plastic belt, with bigger transmission force; when no need stacking function, just directly output from the side by the pass function;Also, can form two sets of different sizes cloth stacking side by side; the overall structure is compact and more convenient to plus additional equipment; you can choose the foot pedal switch, easier control by the operator.

New multi-functional bath commercial towel folder laundry bed sheet folding machinery.

All specifications subject to change without notice

● Adopt 10-inch color-increasing touch screen programmable computer control , each station has a statistical function , accurately measure the amount of feed , easy for the operator to manage .

● With station feeding function , high working efficiency and saving labor cost.

● It has the function of absorbing and smoothing the linen to improve the flatness of linen.

● The feeding speed is controlled by frequency conversion to adapt to the ironing process of different linens.

● The feeding and conveying platform can automatically expand and contract , can reach feed the function of wax doth and pillowcase , and it can also make the manual feeding of bed sheet quilt cover.

● The spreading manipulator is driven by a servo motor to accurately measure the length of the linen and keep the linen at the set feeding position

● Combined with high-speed ironing machine and folding machine , it can make synchronous linkage function.