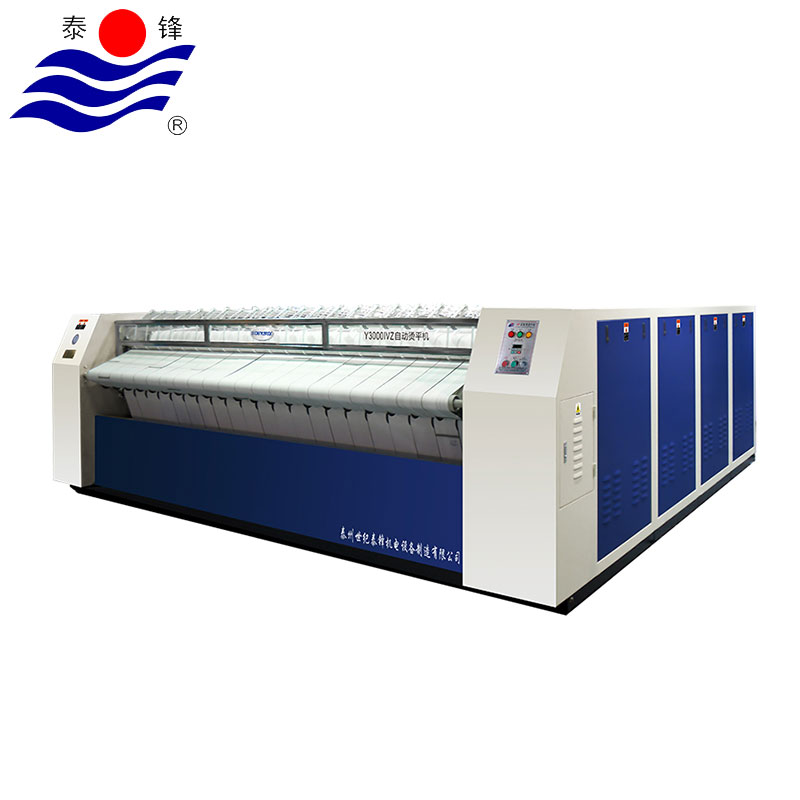

automatic ironing machine

1. The name and type of the machine.

Y Ironing Machine

2. Function, feature of the machine.

The machine uses an electric motor and an imported frequency inverter, so the ironing speed can be adjusted in a stepless manner according to the width of cloth, different conditon of steam supply.

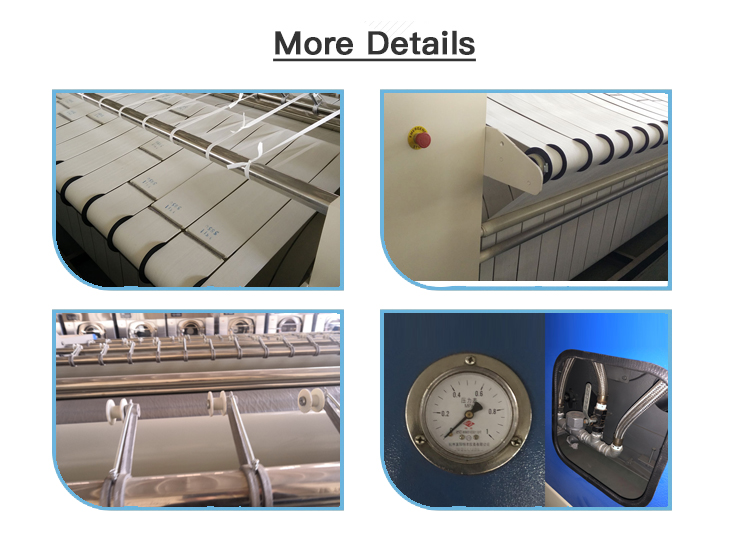

Rollers are made of Φ800 stainless steel. Other components are galvanized or being antiseptic treatment.

Quick heating effect. Direct heating type of drum. The utilization rate of effective contact surface is more than 85%.

Overload protection and emergency stop devices.

Advanced transmission design for better ironing results.

3. Specification and Accessories

| MODEL | Y1800I Z/D/R | Y2800IZ/D/R | Y2800IIZ/D/R | Y3000IZ/D/R | Y3000II Z/D/R | Y3000IIIZ/R | |

| Ironing Length (mm) | Unlimited | Unlimited | Unlimited | Unlimited | Unlimited | Unlimited | |

| Ironing Width (mm) | ≤1800 | ≤2800 | ≤2800 | ≤3000 | ≤3000 | ≤3000 | |

| Ironing Thickness(mm) | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Roller Diameter(mm) | Φ800 | Φ800 | Φ800 | Φ800 | Φ800 | Φ800 | |

| Roller Speed (r/min) | 0-3 | 0-3 | 0-8 | 0-3 | 0-8 | 0-12 | |

| Ironing Speed (m/min) | 0-7 | 0-7 | 0-19.9 | 0-7 | 0-19.9 | 0-30 | |

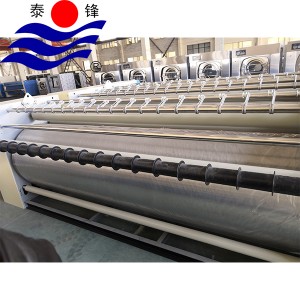

| Steam Pressure(Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |

| Different Heating Method Consumption | Steam (kg/h) | 50 | 80 | 150 | 85 | 150 | 230 |

| Electric (kw) | 24 | 30 | 60 | 35 | 72 | / | |

| Gas (m3/h) | 6 | 8 | 16 | 8 | 16 | 24 | |

| Liquid Gas (kg/h) | 3 | 4 | 8 | 4 | 8 | 12 | |

| Motor Power (kw) | 0.55 | 0.75 | 1.5 | 0.75 | 1.5 | 2.2 | |

| Dimension (mm) | 2670×1580×1350 | 3820×1580×1350 | 3820×2490×1350 | 4050×1580×1350 | 4050×2490×1350 | 4050×3420×1350 | |

| Weight (kg) | 1150 | 1900 | 3100 | 2000 | 3300 | 4700 | |

| MODEL | Y3000IVZ/R | Y3000VZ/R | Y3300IIZ/R | Y3300IIIZ/R | Y3300IVZ/R | Y3300VZ/R | |

| Ironing Length (mm) | Unlimited | Unlimited | Unlimited | Unlimited | Unlimited | Unlimited | |

| Ironing Width (mm) | ≤3000 | ≤3000 | ≤3300 | ≤3300 | ≤3300 | ≤3300 | |

| Ironing Thickness(mm) | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Roller Diameter(mm) | Φ800 | Φ800 | Φ800 | Φ800 | Φ800 | Φ800 | |

| Roller Speed (r/min) | 0-16 | 0-20 | 0-8 | 0-12 | 0-16 | 0-20 | |

| Ironing Speed (m/min) | 0-40 | 0-50 | 0-20 | 0-30 | 0-40 | 0-50 | |

| Steam Pressure(Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |

| Different Heating Method Consumption | Steam (kg/h) | 290 | 370 | 170 | 250 | 330 | 410 |

| Gas (m3/h) | 32 | 40 | 16 | 24 | 32 | 40 | |

| Liquid Gas (kg/h) | 16 | 20 | 8 | 12 | 16 | 20 | |

| Motor Power (kw) | 3 | 4 | 1.5 | 2.2 | 3 | 4 | |

| Dimension (mm) | 4050×4340×1350 | 4050×5270×1350 | 4350×2490×1350 | 4350×3420×1350 | 4350×4340×1350 | 4350×5270×1350 | |

| Weight (kg) | 6000 | 7200 | 3350 | 4750 | 6100 | 7300 | |

1)Operational manual with English will be given at the time of dispatch of machine.

4. Documentation

2)All our machines guaranteed for trouble free performance for a period of 12 months from commissioning.

3)Copy of ISO 9001 and CE certificate.

5. Delivery data and service after sell

1) Payment Terms

LC, WU,T/T

30% in advance, 70% before delivery.

2) Delivery Date

15-30 days upon your order Qty

3) Service After Sell

Installation and service after sell for free for one year, and with spare parts for one years. The air ticket from china to Client’s and Client’s to china will be paid by the buyer and the buyer should supply our engineer’s room and food!